Advantages of Charcoal Making Machine – Energy-saving and Eco-friendly

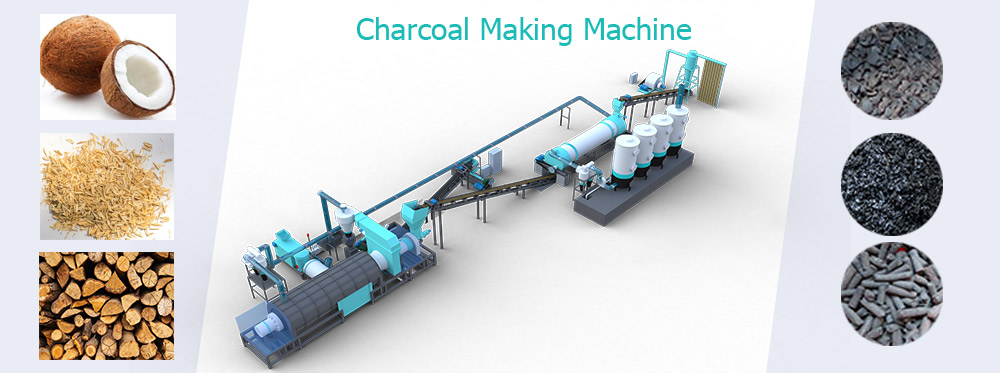

Charcoal making machine is designed to produce charcoal with high carbon content. It is a continuous process and the end product is usually a briquette that is 83% carbon. The screw part of the charcoal making machine for sale can improve the quality of the final product. It can be used for a wide range of production processes, including firewood. You can choose the type of briquetting device that suits your needs and preferences. Listed below are the advantages of briquetting machine.

First of all, this machine is used to turn biomass waste materials into charcoal. It uses the pyrolysis process under an oxygen-free environment to create char. It is a great way to conserve resources while gaining good profits. In addition to its resource utilization, this machine can be found in different types. The Beston group has been manufacturing small charcoal making machine for several years. The company’s professional team and advanced technology make the equipment energy-saving and has excellent customer support. The price for this equipment is reasonable and varies depending on the type of machine you need.

The most important feature of a good charcoal making machine is its heat-use ratio. During the process of burning raw materials, the temperature must rise above 180°C. Then, the moisture content is less than 15%. Using a dryer is necessary if the materials contain more than 15% water. The materials that enter the reactor have already been heated. As the temperature rises, oil gas will be generated. The material will then burn continuously to form charcoal. The auto screw discharger will deliver the charred charcoal to the charcoal tank. The tar and wood vinegar will be collected in separate tanks.

The Beston biochar production equipment for sale is energy-saving and eco-friendly. It uses advanced biomass pyrolysis technology and can be used for small-scale or industrial applications. The Beston equipment is compatible with all types of biomass waste, sludge, and food waste. It is equipped with an automatic screw discharger and a drying system. The charred material will be delivered to the charcoal tank. The wood charcoal is a perfect fuel source.

A charcoal making machine has many advantages to the addition of your business. However, the easiest to see is how it can add probability and growth. If you have been looking for an easy way to grow your business, please reach out to us to discuss the addition of a charcoal making machine.