Revolutionizing Waste Management: Unraveling the Intricacies of Plastic Pyrolysis Plants

In the relentless pursuit of sustainable waste management, plastic pyrolysis plants emerge as the unsung heroes, orchestrating a transformative process that breathes new life into discarded plastics. This cutting-edge technology transcends conventional recycling methods, offering a sophisticated approach to tackling the mounting plastic waste crisis.

The Essence of Plastic Pyrolysis

At its core, a plastic pyrolysis plant is a marvel of innovation, designed to break down plastic waste through the application of heat in the absence of oxygen. This intricate dance of molecular transformation not only minimizes environmental impact but also harnesses the latent energy embedded in plastic polymers.

Decoding the Pyrolysis Symphony

- Feedstock Introduction: The overture begins as plastic waste, the feedstock for the process, is introduced into the pyrolysis reactor, setting the stage for a molecular metamorphosis.

- Pyrolysis Reactor Activation: The heart of the plant, the pyrolysis reactor, comes alive with controlled heat, initiating the thermal degradation of plastics into valuable byproducts.

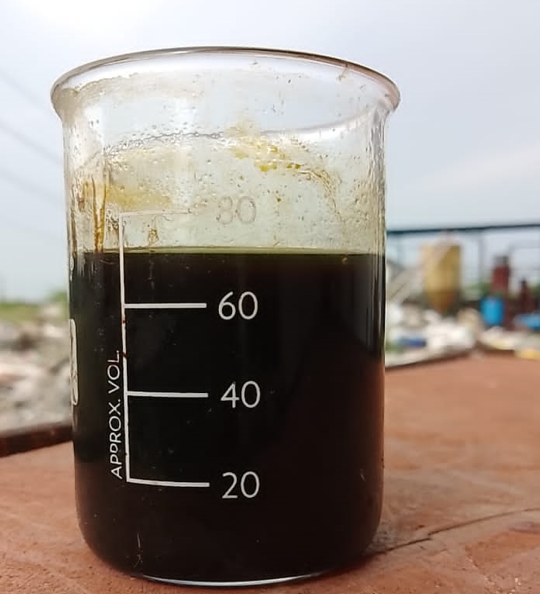

- Gas and Oil Generation: As the temperature rises, plastics undergo pyrolysis, transforming into gases and liquid oil. This process not only deconstructs complex polymers but also yields substances with diverse applications.

- Condensation and Collection: The liberated gases and oil are tactfully condensed and collected, paving the way for the recovery of valuable resources from what was once considered unmanageable plastic waste.

The Alchemy of Plastic Transformation

Catalytic Influence

One of the distinguishing features of advanced plastic to oil machine is the integration of catalysts into the process. These catalysts enhance the efficiency of pyrolysis reactions, optimizing the yield of valuable products while minimizing undesired byproducts.

Selective Pyrolysis

In the realm of precision, selective pyrolysis becomes the guiding principle. Different plastics have distinct thermal decomposition points, and the plant can be fine-tuned to target specific polymers selectively. This tailored approach maximizes resource recovery and minimizes waste.

Applications Across Environmental Frontiers

Resource Recovery

Plastic pyrolysis plants redefine the narrative of plastic waste by turning it into a resource. The generated oil, often referred to as pyrolysis oil or bio-oil, can find applications as a fuel source or as a feedstock for various industrial processes.

Circular Economy Advancement

In the pursuit of a circular economy, where resources are reused and recycled, plastic to fuel machine play a pivotal role. They bridge the gap between the end-of-life stage of plastics and the creation of new, useful materials.

Environmental Impact Mitigation

The environmental ramifications of plastic pollution are far-reaching. Plastic pyrolysis plants contribute to mitigating this impact by reducing the volume of plastic waste in landfills, preventing marine pollution, and curbing the need for new plastic production.

Beyond Waste Management: Environmental and Economic Impacts

Emissions Control

While the pyrolysis process unfolds, stringent measures are in place within plastic pyrolysis plants to control emissions. This ensures that the environmental benefits of waste reduction are not offset by harmful byproducts.

Economic Viability

In the realm of sustainability, economic viability is paramount. Plastic pyrolysis plants not only address the ecological aspect of waste management but also present an economically viable solution. The recovery of valuable resources from plastic waste aligns with the principles of a sustainable and circular economy.

Looking Ahead: Future Frontiers of Plastic Pyrolysis Plants

As technology advances, the landscape of waste management evolves. The future envisions further refinement of plastic pyrolysis plants, with improvements in process efficiency, scalability, and integration with other waste-to-energy systems. These strides pave the way for a more comprehensive and sustainable approach to tackling the global plastic waste crisis.

In conclusion, plastic pyrolysis plants stand as pioneers in the green revolution against plastic pollution. Their ability to transform discarded plastics into valuable resources not only addresses the urgent need for waste management but also contributes to the broader goal of creating a sustainable and circular economy. More information on Beston Group here.