Key Facts About Tyre Pyrolysis Equipment For Sale

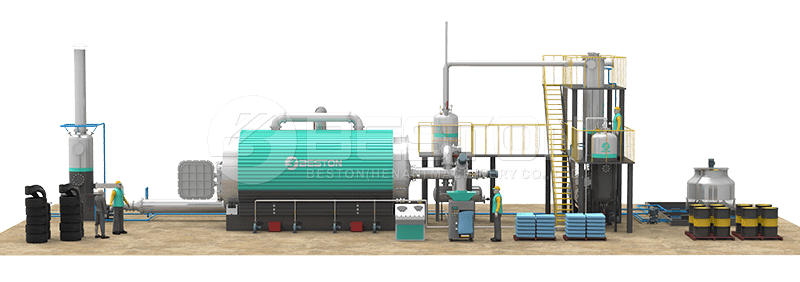

Waste tyre pyrolysis plant is used to convert black rubber waste from scrap road tires into carbon black, pyrolysis oil, combustible gas, and steel. All of those four aforementioned resources can fetch large profits in the commodity markets. Pyrolysis oil, for example, is a heavy fuel oil that can be used to power all sorts of industrial machines. The oil can also be refined into diesel oil or gasoline using distillation equipment. If you want to start tyre recycling business, you need to find a suitable tyre pyrolysis plant for sale first.

There is a great selection of tire pyrolysis equipment for sale because the rubber recycling industry is booming at the moment. More and more people are waking up to the damage waste tires are causing to the planet when they are sent to seafills, landfills, and waste incinerators. As a result, many countries now offer green grant schemes and tax rebate incentives to businesses looking to invest in a waste tire pyrolysis plant.

The continuous tyre pyrolysis plant is fully automatic. This is possible thanks to advanced dedusting systems equipped to all plants from Beston. The dedusting systems use a combination of water washing, water spray, ceramic ring adsorption, and activated carbon adsorption cleaning technologies to ensure emissions from the rubber pyrolysis plants contain no pollution. The EU now has very strict emissions regulations, so choosing plants with activated carbon absorption towers is vital for businesses located in Europe.

The heat re-utilization features of modern pyrolysis plants also make them very energy efficient and thus environmentally friendly. All of the combustible gas produced during rubber pyrolysis reactions is used to refuel the reactor furnace. By setting up somewhat of a self-perpetuating process, the energy costs associated with fully continuous pyrolysis machines can be kept low.

The main difference between semi-continuous and continuous tire pyrolysis plants besides their automation levels is the reactor configuration. Semi-continuous models are typically equipped with rotary reactors, while continuous models are equipped with horizontal (fixed) reactors. A horizontal pyrolysis reactor offers much more stability and has better energy efficiency. Continuous tyre to oil plant can also operate 24/7 with a very limited manual workforce as they have automatic dischargers as well as automatic feeders.

Tire recycling companies that are looking to process hundreds of tons of scrap tires each week are certain to find fully continuous pyrolysis plants to be a better investment option. Some of the top plant models have 30+ ton daily capacities. Of course, the bigger the processing plant the higher the price tag. A quick online search reveals that the price of a 30-ton continuous waste tire recycling plant can exceed thousands of dollars.

When it comes to accessing the best tire pyrolysis plant price, investors need to be ready to explore the overseas marketplace. There are lots of low price suppliers in China and the quality of tire to oil machines from the region is very high. Here is a website for your reference: https://wasterecyclingplant.com/waste-tyre-pyrolysis-plant/.