Converting Sugarcane Bagasse Into Biochar

There is a good machine which can recycle sugarcane – bagasse charcoal machine. Sugarcane is a very profitable crop that is grown in multiple countries around the world, particularly those with warm, humid climates. Some the biggest produced of the crop include Brazil, India, Thailand and China. Some of the main applications of a sugarcane harvest include food manufacturing and cosmetic manufacturing. The most valuable part of sugarcane is the sugary juices, but the sugarcane bagasse is also a valuable fibrous byproduct that can be converted into charcoal by sugarcane bagasse charcoal machine and sold to the fuel industry.

Transforming sugarcane bagasse into charcoal is a fairly simple process and it can be completed using some very basic tools or a specialized automated sugarcane bagasse charcoal machine. The most rudimentary way to create sugarcane bagasse charcoal briquettes involves the use of a 50-gallon metal drum. First, the drum needs to be prepared to become a kiln, so air intake holes need to be drilled into the three main sections of the barrel. These holes can be opened or closed to regulate the amount of oxygen entering the carbonization furnace. Do you know carboniser machine cost? Some manufacturers provide fair price.

After the barrel has been setup as a kiln, the bottom section is filled with raw sugarcane bagasse. If the bagasse has a moisture content exceeding 18%, it will need to be dried first to ensure a high-quality end product. A fire is then lit in the bottom section of the barrel before more raw materials are added. It’s important to avoid packing the bagasse down too tightly. When the fire reaches the top of the drum, the lid should be put on and all of the air vents closed apart from the ones in the bottom section.

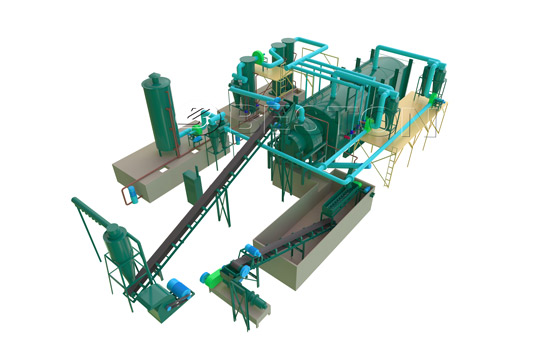

As carbonization starts to take place, the volume in the drum will decrease and more sugarcane bagasse should be added to restrict air intake and ensure the highest quality charcoal is produced. Companies that use a bagasse charcoal machine do not have to worry about manually adding more raw materials to the furnace or controlling the air intake into the drum, as such a biochar plant automates all of those processes.

As soon as the middle section of the drum has all been converted into charcoal, the vents in that section should be closed. Once the top section is carbonized, all the air vents in the drum should be closed and the kiln left to cool down for around 8 hours. After the cool-down period has passed, the sugarcane bagasse charcoal can be removed from the drum and shaped into high-grade biochar briquettes.